Even so, not all choices relating to process validation vs process verification are that easy to make. If you’re thinking of no matter whether you must verify or validate a process, then get started with the IMDRF advice on process validation.

Process validation performs an important job in quality assurance by supplying assurance that a manufacturing process is below Handle and capable of regularly generating items that meet consumer specifications.

Also, process validation performs an important part in ensuring solution basic safety. It can help determine opportunity dangers and deviations that would compromise the safety of the top goods. By addressing these risks and deviations, corporations can make sure their products and solutions are safe for individuals to utilize.

This involves the gathering and analysis of data in the process layout stage as a result of professional generation to ascertain scientific evidence that a process is effective at consistently offering top quality goods.

Ongoing process monitoring is also a critical prerequisite outlined by the EMA. This includes the frequent monitoring and Assessment of process information making sure that the process remains inside of a state of Command.

Process validation is defined as the gathering and evaluation of data, from your process design phase in the course of generation, which establishes scientific evidence that a process is capable of continually providing top quality goods.

Threat evaluation plays a vital role in process validation. By determining possible threats and areas of issue, organizations can focus their validation endeavours on crucial process parameters and techniques.

Use this process validation report template while in the pharmaceutical industry to document every little thing effectively.

Process validation may be outlined because the documented evidence that establishes a high degree of assurance that a selected process will regularly generate a product that meets its predetermined specs and good quality features.

However PV approach can limit to only These device processes which can be evaluated to own affect due to variance in batch dimension.

QA shall website put together the process validation report by compilation of BMR knowledge and QC analytical report as per Annexure four

Process Qualification: Through process qualification, machines and processes are tested beneath simulated or genuine conditions to ensure reliability.

In the extremely regulated and quick-paced planet of manufacturing, top quality Handle is of utmost relevance. Firms have to be sure that their processes are responsible, dependable, and effective at continually manufacturing products which meet up with the very best expectations. This is where process validation comes into play.

Concurrent validation lets output to continue while website validation is done, noticeably cutting down lead situations. This is particularly valuable in situations wherever timely availability of your solution is essential.

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Robert Downey Jr. Then & Now!

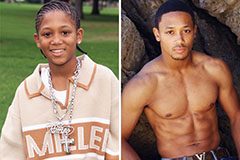

Robert Downey Jr. Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!